S.Aishwariya discusses the leap of technical textiles, the latest innovations and their expanding market potential in the field of fashion and apparel.

Journey Of Textile Fibres

1. The first-generation textile fibres were those that were procured directly from the nature and that era lasted for 4,000 years. The second generation consisted of man-made fibres like nylon and polyester, which were a result of the efforts taken by chemists in 1950, to evolve with materials that resemble natural fibres. The third generation includes fibres from under-utilised natural resources to meet the needs of the ever-growing population. These are not just alternatives or addition to the existing natural fibres, but are believed to have diversified characteristics that can aid in various application areas. As a result of shifts in textile industry, the technical textile sector is growing in developed economies with application in diverse fields

2. During the industrial age from 1775 to 1850, natural fibre extraction and production was at its peak. The period between 1870 and 1980 marked the epitome of synthetic fibre exploration at the end of which the word 'technical textiles' was coined. After a decade, more innovations, including flexible materials, extremely light-weight structures, 3D moulding, evolved in the field of smart textiles. The twentieth century marks the information age where space suits, robots, self-cleaning textiles, panel electroluminescence, chameleonic textiles, body monitoring garments are commercially successful.

3. Synthetic polymers have huge potential and abundant functionality that can outperform natural fibres. For example, bio-polymers derived from corn have been extensively used in creating high-tech fibres with supreme functionality with application in biodegradable and flushable diapers. Such advanced techniques have made possible fibres that dissolve in water, thereby reducing dumping in sanitation pipes. The compostable pads are designed so that those have 100 per cent bio-degradable natural materials in them. These researches have definitely improved the quality of life.

Current Research

Conventional textiles are woven or knitted materials whose use is based on test results. In contrast, technical textiles are developed based on the user applications. Their applications include space suits, artificial kidney and heart, pesticide-repellent clothing for farmers, road construction, bags to prevent fruits from being eaten by birds and efficient water-repellent packaging materials.

The different branches of technical textiles include clothing, packaging, sports and leisure, transport, medical and hygiene, industrial, invisible, oeko-textiles, home, safety and protective, building and construction, geo-textiles and agro-textiles.

Comparing the consumption trends with the rest of the world, India has a share of 35 per cent in textiles for functional applications in garments and shoes (clothtech), 21 per cent in textiles for packaging applications (packtech), and 8 per cent in sports textiles (sportech). The rest accounts for 36 per cent. But globally the leading sector is textiles used in the construction of automobiles, railways, ships, aircraft and spacecraft (mobiltech), which is 25 per cent of the over technical textiles market, followed by industrial textiles (indutech) at 16 per cent and sportech at 15 per cent, with all other fields comprising 44 per cent. Products that can boost the industry include webbing for seat belts, diapers and disposables, geotextiles, fire retardant fabrics, ballistic protective clothing, filters, non-wovens, hoardings and signages.

The biggest strength of India is its huge resource network and a strong domestic market. India's textile industry has woken up to the enormous potential of the technical and non-woven sectors. Strong government support through policies, introduction of appropriate legislation and development of proper tests and standards can make a positive impact on this industry's growth. The prime need of the hour is that of more trained personnel. There should be more plans to train workers and to start incubation centres for lab-to-land experiments.

The significant contributions of the research associations in the country are highly commendable. They include the Ahmedabad Textile Industry Research Association (ATIRA), the Bombay Textile Research Association (BTRA), the South India Textile Research Association (SITRA), the Northern India Textile Research Association (NITRA), the Wool Research Association (WRA), the Synthetic & Art Silk Mills' Research Association (SASMIRA) and the Man-made Textile Research Association (MANTRA). Thirty three integrated textile parks, which include five in Tamil Nadu, four in Andhra Pradesh, five in Karnataka, six in Maharashtra, six in Gujarat, two in Rajasthan, and one each in Uttar Pradesh and West Bengal, should work in cohesion to bring the entire supply chain under one roof.4,5

Geo-Textiles

Textiles used to cover the earth or floor are categorised as geotextiles. Such textiles are used today for construction of houses, bridges, dams and monuments that increases their life. [6]

Cool Fabrics

Technical fabrics developed by Adidas help in maintaining normal body temperature at 37 degrees C. Examples are labels like Clima 365, Climaproof, Climalite that serve this purpose. Elextex consists of a lamination of five layers of conducting and insulating textiles forming an all fabric touch sensor (1 cm2 or 1 mm2). It is certified by the Bureau of Indian Standards (BIS) and can be sewn, folded and washed. These have huge scope in sports textiles.

Biomimetics

Biomimetics is the design of new fibre materials, systems or machines through the study of living systems, to learn from their high-level functional mechanisms and to apply those to molecular and material design. For example, imitation of how lotus leaf behave with water droplets; the surface is microscopically rough and covered by a coating of wax like substance with low surface tension.

When water falls on the surface of the leaf, the air trapped forms a boundary with water. The contact angle of water is large because of the wax like substance. However, other factors like surface texture also affect the repellence. The criterion for water repellence is that the rolling angle should be less than 10 degree. This idea is taken and recreated as a fabric. The potential material can reduce the effort in sports like swimming.

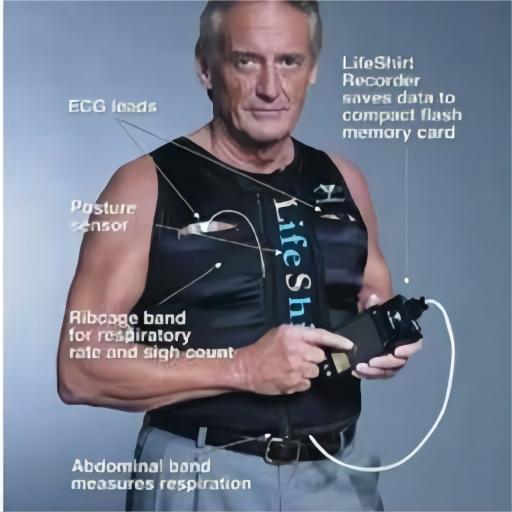

Vivometrics

The electronics integrated into textiles can read body conditions like heart beat, blood pressure, calories burnt, lap time, steps taken and oxygen levels. This is the idea behind Vivometrics, also called body monitoring garments (BMG). It can save the life of a new-born or of a sportsperson.

The brand Life has conquered the market with its efficient body monitoring vest. It functions like a textile ambulance in analysing and altering for help. A wide range of cardio-pulmonary information is collected based on cardiac function, posture, activity records along with blood pressure, oxygen and carbon dioxide levels, body temperature and movements. It serves as a huge innovation in the field of sports and medical textiles.

Camouflage Textiles

The colour-changing surface of the chameleon is observed and recreated in the textile material. Camouflage textiles dealing with the concealment of objects and people by imitating surroundings were introduced during World War II. This technique uses fibres that help in blending with the background, something that can reflect the background like a mirror and also be strong like carbon.

These fibres are used along with cotton and polyester to create camouflage textiles. Initially only two patterns featuring the colour and pattern were designed to resemble a scene of a thick forest with shades of green and brown. But now, seven variations are designed with better functionality and deceptiveness. It includes spacing, moving, surface, shape, shine, silhouette and shadow. The parameters are critical in spotting a person from a long distance. Evaluation of camouflage textiles is difficult as it differs with sunlight, humidity and season. So people with colour blindness are employed to detect visual camouflage. Subjective analysis, quantitative analysis and assistance of electronic equipment is taken for testing of the materials.

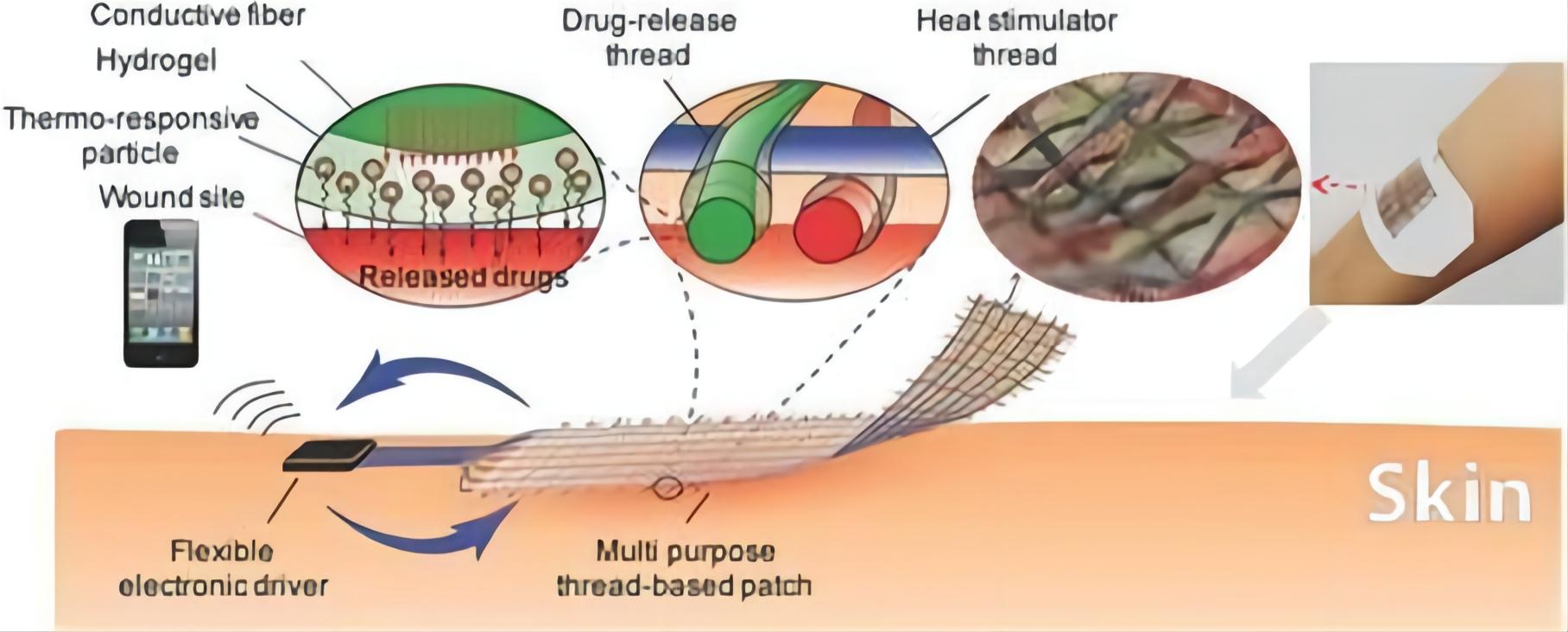

Textiles For Drug Delivery

Advancements in the health industry now combine textiles and medicine.

Textile materials can be used to enhance the effectiveness of drugs by providing a mechanism for controlled release of drugs over a sustained period of time and by delivering high concentration of drugs to the targeted tissues without serious side effects. For example, Ortho Evra transdermal contraceptive patch for women is 20 cm in length, consists of three layers and is approved by the US Food and Drug Administration.

Use Of Gas Or Plasma For Textile Finishing

The trend started in 1960, when plasma was used to change the fabric surface. It is a phase of matter distinct from solids, liquids and gases and is electrically neutral. These are ionised gases made up of electrons, ions and neutral particles. Plasma is partially ionised gas formed by neutral species like excited atoms, free radicals, meta stable particles and charged species (electrons and ions). There are two types of plasma: vacuum-based and atmospheric pressure-based. The surface of the fabric is subjected to electron bombardment, generated in the electric field of plasma. Electrons hit the surface with a wide distribution of energy and speed and this leads to a chain session in the upper layer of the textile surface, creating cross linking thereby reinforcing the material.

Plasma treatment leads to etching or a cleaning effect on the fabric surface. The etching increases the amount of surface area which creates better adhesion of coatings. Plasma affects the target and is very specific in nature. It can be used in silk fabrics causing no change in the target's physical properties. Aramids like Kevlar, which lose strength when wet, can be more successfully treated with plasma than by conventional methods. One can also impart a different property to each side of the fabric. One side can be hydrophobic and the other hydrophilic. Plasma treatment works for both synthetic and natural fibres with particular success in anti-felting and shrink resistance for wool.

Unlike traditional chemical processing that requires multiple steps to apply different finishes, plasma allows the application of multifunctional finishes in a single step and in a continuous process. Woolmark has patented the sensory perception technology (SPT) that adds smell to fabrics. US firm NanoHorizons' SmartSilver is a leading technology in providing anti-odour and anti-microbial protection to natural and synthetic fibres and fabrics. Heart attack patients in the West are being cooled in an inflatable tent during operation to reduce the risk of a stroke by lowering the body temperature. A new natural bandage has been developed using plasma protein fibrinogen. Since it is made from human blood clot, the bandage need not be removed. It dissolves in the skin during the healing process.15

Sensory Perception Technology (SPT)

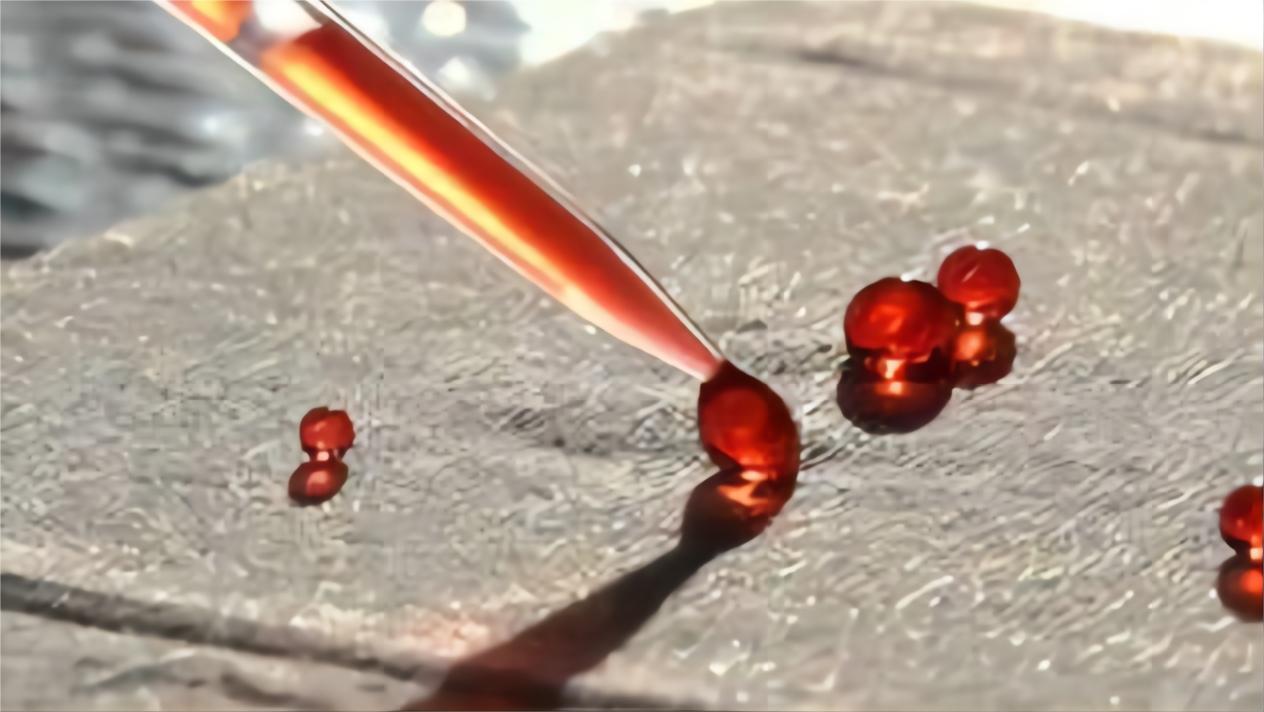

This technology captures fragrances, essences and other effects in micro-capsules that are affixed onto fabrics. These micro-capsules are miniature containers with a protective polymer coating or melamine shell that guards the contents from evaporation, oxidation and contamination. When these fabrics are used, some of these capsules break open, releasing the contents.

Microencapsulation

It is a simple process consisting of encapsulating liquid or solid substances in sealed micro spheres (0.5-2,000 microns). These microcapsules gradually release active agents by simple mechanical rubbing which ruptures the membrane. These are used in deodorants, lotions, dyes, fabric softeners and flame retardants.

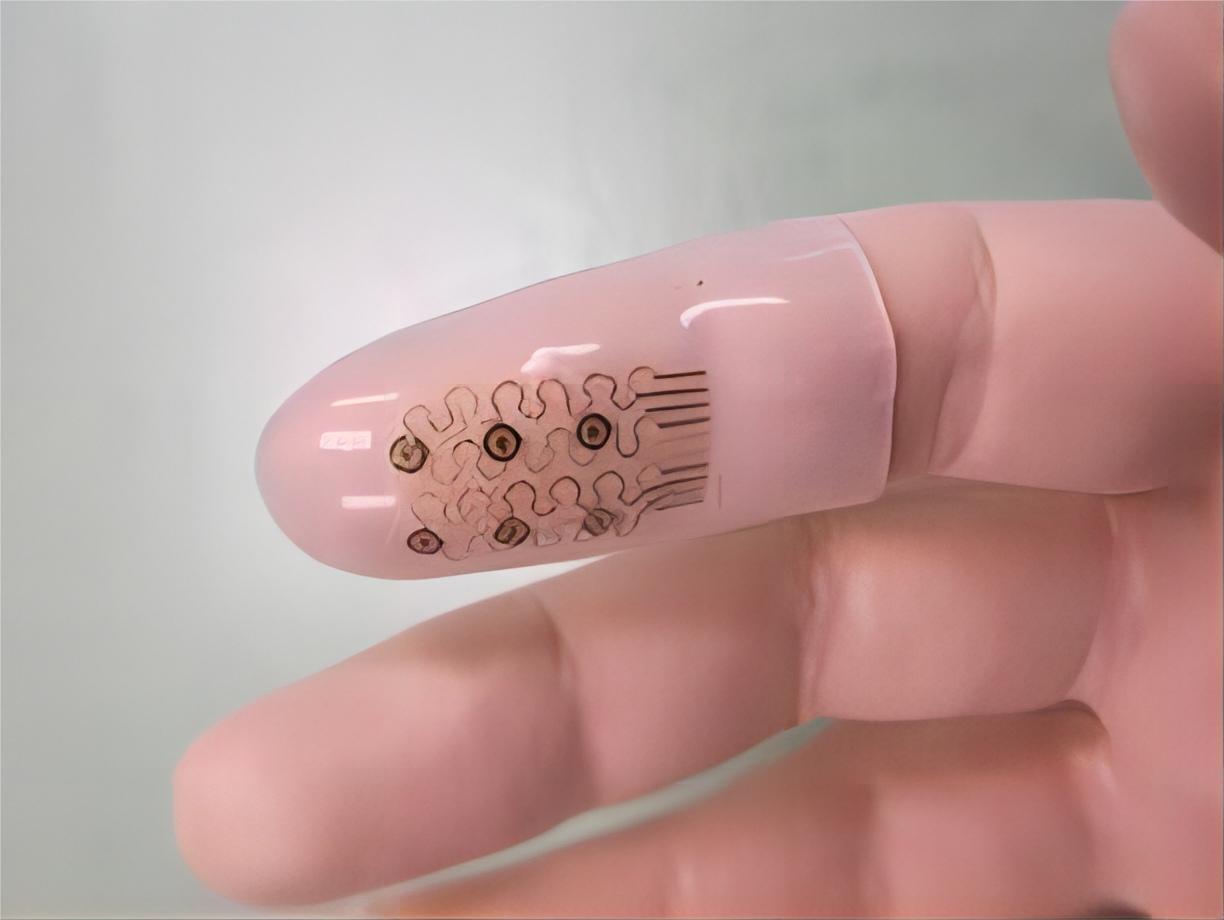

Electronic Textiles

Wearable electronics such as this ICD jacket from Philips and Levi's, with its built-in cell phone and MP3 player, run on batteries. A garment embedded with technology is not new, but continuous advancements in smart textiles make them more feasible, desirable and practical in application. Wires are sewn into the fabric to connect the devices to a remote control and a microphone is embedded in the collar. Many other manufacturers later came up with intelligent fabrics that hide all the wires.

Long distance shirt was yet another very interesting simple innovation. This e-textile concept works in a way that when one hugs themselves the t-shirt glows. It was marked as one of the interesting inventions in of 2006. It gives the wearer a feeling of being hugged.

When a hug is sent as a message or through bluetooth, the sensors react to it by creating the warmth, heart beat rate, pressure, timing of a hug by the virtual person in real. This shirt is also washable that makes it even more apprehensive to ignore. Another invention, Elextex consists of a lamination of five layers of conducting and insulating textiles forming an all fabric touch sensor (1 cm2 or 1 mm2). It can be sewn, folded and washed.19-24 All these help us understand the way electronics and textiles can be integrated to improve quality of life.

This article has not been edited by XiangYu Garment staff it was citeed from https://www.technicaltextile.net/articles/tech-textile-innovations-8356

Post time: Jul-11-2022